History

Dutch Mill Group is committed to providing the best dairy products in the ASEAN region with Thai craftsmanship under the management approach that focuses on the innovative production and continuously improve the work process for efficiency to meet customer satisfaction increase competitiveness by creating good quality products for the health of all Thai people.

As Number 1 in the dairy industry for many years running, Dutch Mill wins the hearts of consumers and achieved top sale in Thailand. We aim to give back to society by giving continuously promoting the health of Thai people, creating a good society, and caring for the environment sustainably.

From small beginning, we have expanded our business to become a large regional business.

Dutch Mill Company Limited was established on January 27, 1984, in the name of "Pro Food Company Limited" by a group of food scientists from Kasetsart University who foresee the importance of "milk", which is a food that has enormous benefits. Dairy is also important to economical growth as it enhance the quality of life of farmers. We strive to develop dairy products for the better health of Thai people. Started with yogurt production and drinking yoghurt under the name “Dutch Mill” with “Pro Mart Co., Ltd.” as its distributor.

The first factory was established in Nakhon Pathom province.

“Dutch Mill” dairy products became popular & widely known in every household quickly. Dutch Mill established its first factory on Phutthamonthon Sai 8 Road, Nakhon Chai Si District. Nakhon Pathom province to serve the continuous growth of consumer demand. We developed new products into the market, consisting of “Pasteurized Drinking Yoghurt” and “UHT Drinking Yoghurt.”

When the market in Bangkok area kept growing Dutch Mill has expanded sales channels for Dutch Mill “Pasteurized Drinking Yoghurt” to the provincial area with a Direct sales system featuring the workforce of our "Dutch Mill Lady" that you might see on the streets or at your doorsteps across the country.

Expanded the second factory in Nakhon Sawan province.

To support the growth and success of the business, in the year 1997, Dutch Mill established a second factory in Phayuha Khiri District. Nakhon Sawan Province. New world-class tools such as MRPII, SAP, TQM and TPM to enhance efficiency and the competitiveness of the factory capability.

On a global stage, Dutch Mill also exported dairy products to various countries in Asia, including China, Taiwan, the Philippines, Singapore, Malaysia, Vietnam, Cambodia, Laos, Myanmar, Brunei, Maldives, Bhutan, Palestine, and the United Arab Emirates, and eager to bring Thailand’s number 1 products to the many other countries in the future.

Companies in the Dutch Mill Group

1. Dutch Mill Company Limited (DMC)

Manufacture and sale of dairy products produced by pasteurization process. Dutch Mill Pasteurized Drinking Yogurt, Dutchie Yoghurt, Dutch Mill Pasteurized Milk and Delight Probiotic drink, Dutch Mill Proyo.

2. Dairy Plus Company Limited (DPC)

Manufacture and sale of dairy products produced by UHT process. Dutch Mill UHT Drinking Yogurt, DNA Soy Milk, Dutch Mill Soy Secretz, Dmalt Malt extract drink.

3. DMDL Public Company Limited

Distributing and distributing products of affiliated companies including taking care of sales channels distribution center and Arabus business.

Vision of Dutch Mill Group

To be one of the best manufacturing and marketing companies of dairy products in ASEAN.

Mission of Dutch Mill Group

- Innovate excellent products and services that lead to customer satisfaction.

- Upgrading employees' competency by emphasizing learning and endless self-improvement.

- Continuous improvement of work processes to create better quality.

Corporate Core Values

Dutch Mill Group is committed to prioritizing "quality" by adhering to the 3 principles of work:

Production Technology

Manufacturing technology and quality control

One of the most important elements of Dutch Mill's success is the attention to quality in every step of the way. This is the basic practice of the company to build confidence food safety and good benefits before reaching the consumer starting from a dairy farm raw milk collection center process of production, packaging, and distribution before delivering to consumers to provide standardized products with 100% quality assurance.

Priority is quality in every step. "Food Safety” with GMP, GHPs and HACCP standards, close inspection in every production process to ensure compliance with international quality system standards, including the General Principles of Food Hygiene (GMP, GHPs) and use the Hazard Analysis System. Also (HACCP) which focus on critical control point in food production ensuring that Dutch Mill products are safe from physical contamination and chemical contamination.

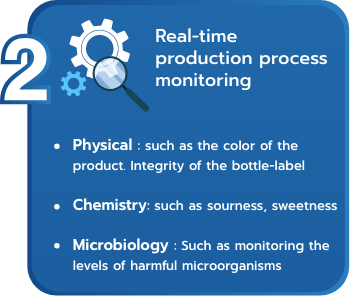

The company has developed stringent quality control practices specific of Dutch Mill focusing on important points by adhering to the following principles :

GMP Standard : Good Manufacturing Practice

Provide you with the "confidence" that every product conforms to international quality standards.

G = GOOD

M = MANUFACTURING

P = PRACTICE

GMP Standard : Good Manufacturing Practice

GMP standards are criteria and methods for good production. It is a mark to certify the production quality of the manufacturer that produce food safely and to make consumers confident that the products that leave this manufacturer can be assured. The criteria cover everything from the location of the building to the production process and covering assessment of raw materials, storage, and transportation to the hands of consumers. A GMP-standard factory assures you that it’s safe every step of the way.

GHPs Standard : Good Hygiene Practices

GHPs standards are guidelines and methods for good food production. It is the basic criteria or requirements that are required in production and control to produce food safely from the first step to the last step with an emphasis on protection and eliminate risks that may cause food to be harmful, toxic, or unsafe for consumers, covering from the source of raw materials until the product reaches the consumer.

HACCP Standard : Hazard Analysis and Critical Control Point

HACCP is Hazard Point Analysis and critical control point which is mainly a safety quality management system. There will be CCP or Critical Control Point used in production control covering the prevention of problems from 3 hazards: biological hazards / chemical hazards / physical hazards.

HACCP is now a globally recognized standard that it is effective in ensuring the safety of products that are passed on to consumers.

Dutch Mill has placed great emphasis on quality management processes. We focus on preventing problems and proactive inspection from the first step until the last step.

“Under production processes that are certified by GMP, GHPs and HACCP standards, consumers can be assured that Dutch Mill products are of high quality, safety and hygiene from upstream to downstream to consumers.”

ISO 9001, ISO 14001, ISO 22000 and ISO45001 Standard

To complete the operation and production in accordance with international standards Dutch Mill is also ISO (International Organization for Standardization) accredited by the International Organization for Standardization. ISO measures the quality of various organizations with the same standard around the world.

-

ISO 9001 : 2015 a standard quality management system (Quality Management System: QMS), which is a system used for managing the product delivery process or quality service with a clear plan and can be verify.

-

ISO 14001 : 2015 Environmental Management System Standard for the organization to have an environmental management system at the policy level and organizational plans.

-

ISO 22000 : 2018 Food Safety Management Standard that demonstrates the ability to control food safety hazards along the food chain. There is effective control and inspection in every step.

-

ISO 45001 : 2018 Occupational Health Management Standard And safety at work so that employees in the organization are safe in all aspects, including hygiene, cleanliness, contaminants, and the use of standardize equipment.

Under the ISO quality system, consumers can be confident in Dutch Mill products as it meets the standards in terms of quality, cleanliness, safety, and attention to the environment.

Awards

With constant innovation to pioneer healthy consumer products, Dutch Mill receive various awards throughout the years as the brand signify the consumers’ trust in quality and product safety as well as delicious taste. Dutch Mill Group has received following prestigious awards :

- Reader’s Digest Thailand Trusted Brand 2001-2015

- Thailand Prime Minister’s Export Award

- Thailand Most Admired Brand 2001-2015

- Thailand Prime Minister’s Award for Outstanding Quality Management

- Asian Energy Award

- Thailand’s Most Chosen Brand in Dairy Sector Kantar 2021

- Thailand’s Most Chosen Brand in Dairy Sector Kantar 2022

- Brand Footprint Award Most Chosen Brand 2019